Select State

Someone living in a hotter climate typically won’t have to worry their water tank will freeze over, in contrast to someone who lives in a climate with harsh winters. If you fall into this class of preventing off the elements every year, then you’ll need sure coatings and supplies to stop the water from freezing. Utilizing coatings and composite supplies will add an extra $500 to $1,000 for the ultimate buy worth. Beyond type, you’ll want to think about the kind of materials you’re using on your water tank.

Applications of our steel water tanks

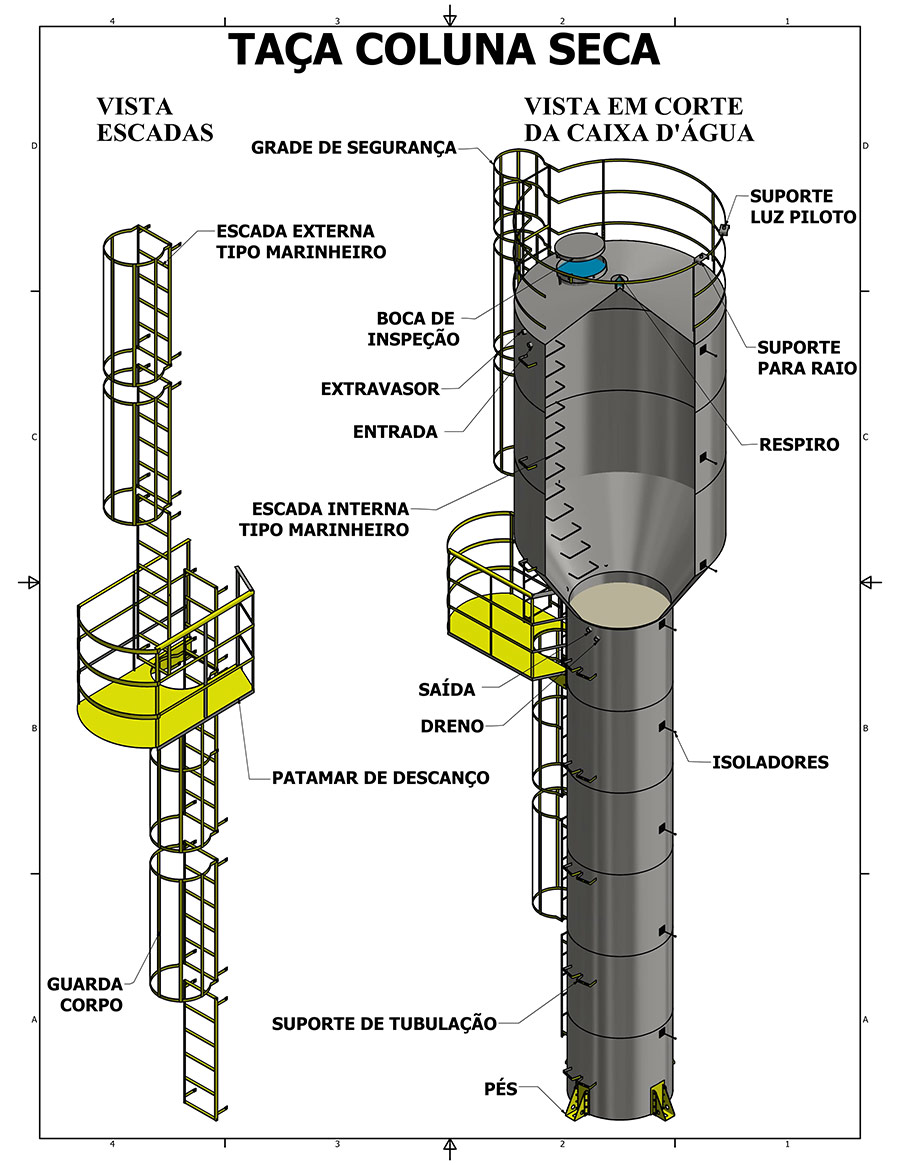

Inside ladders aren't recommended in places the place sustained freezing weather may be anticipated. Safety units for lengthy ladders are required by regulation in all places. Steel reservoirs weigh only about 1/8th as much as concrete ones of the identical capacity. Standard accessories could embrace shell and roof manholes, screened roof vent, inside and/or outdoors ladders, painter’s trolley rail, and connections for pipes as required. Other than the loading from the tank full of water, there are three loads that must be considered in the design of a tank-wind, snow and caixa tipo taça earthquake. Wind load usually relies on an assumed wind velocity of a hundred MPH, though a better velocity is used in some cases. This loading typically is used even in areas the place snow does not happen.

Painting a steel water tank is a good way to guard and prolong the life of your tank, as nicely as improve its aesthetics. The software course of will vary relying on the size of your tank and the tools obtainable to you. Oil-based paints are extra sturdy, stain-resistant, and supply a thorough finish. However, they're more expensive, susceptible to cracking and chipping, and take longer to dry. On the opposite hand, water-based paints dry faster, emit fewer fumes, and are extra resistant to cracking, chipping, and fading. Stainless metal is broadly considered superior to different supplies within the classes of power, sturdiness, and hygiene. Manufacturing tanks from stainless steel maximizes your tank’s anticipated life expectancy.

Highest Quality for your Fire Water Storage Tanks

We produce our modular tanks as a prefabricated package deal for provide. This indicates that the tank comes as a complete construction equipment, which includes all installation supplies (excluding tools). The custom-made silo are as a normal supplied with twine, protection fleece, clamp profile and the Install+ fixing system. We can prefabricate outlets in the diameter of your alternative and weld these into place on the desired location. Depending on the primer and the desired finish, you might have to sand the primed surface lightly earlier than applying the paint.

This technique doesn't increase capacity in a linear style. Generally talking, capability increases with the square root of the tray spacing.High capacity deck designs often use smaller orifices. Smaller sieve holes or valves have a tendency to reduce localized momentum of the vapor flowing by way of the orifices. Essentially, smaller streams have a more difficult time penetrating the froth on the tray deck and subsequently do not carry as a lot entrainment upward. With standard cross-flow trays, aerated froth enters the downcomer from the tray above. As the froth flows into the downcomer, much of the vapor disengages from the liquid and returns to the tray area above, leaving a degree of clarified liquid in the downcomer that flows to the tray under.

This technique doesn't increase capacity in a linear style. Generally talking, capability increases with the square root of the tray spacing.High capacity deck designs often use smaller orifices. Smaller sieve holes or valves have a tendency to reduce localized momentum of the vapor flowing by way of the orifices. Essentially, smaller streams have a more difficult time penetrating the froth on the tray deck and subsequently do not carry as a lot entrainment upward. With standard cross-flow trays, aerated froth enters the downcomer from the tray above. As the froth flows into the downcomer, much of the vapor disengages from the liquid and returns to the tray area above, leaving a degree of clarified liquid in the downcomer that flows to the tray under.Increase capacity in your column with a tray design revamp

This is as a result of higher vapour-liquid contact means better separation at every tray, translating to better column efficiency. Less trays shall be required to realize the same diploma of separation. Attendant advantages embody much less power usage and decrease construction prices. Being lighter, vapour flows up the column and is compelled to pass by way of the liquid, via the openings on each tray.

Operating at Partial Reflux

The effects of the operation situations, typically characterized by hydrodynamic terms similar to froth top, flooding, and strain drop, are essential options for distillation column design, operation efficiency, and column efficiency. When making an attempt to increase column capability past design charges, an operator may discover loss in separation effectivity or high pressure drop, indicative of both vapor phase or caixa tipo taça liquid phase hydraulic limitations. Jet flooding, additionally known as entrainment flooding, is brought on by huge entrainment of liquid to the tray above. As the tray loading increases, a two-phase combination of spray or froth begins to occupy increasingly more of the clear vapor space between the trays. At very excessive vapor charges, the combination fills up the whole tray spacing, causing entrainment of serious quantities of liquid to the tray above. Entrainment also recycles liquid upward, growing tray weir loads, froth peak, and downcomer hundreds.

Distillation Column Internals

If you want a water truck for street mud control or dust suppression on your job site, we're here to assist. We ship all our vehicles globally, so there is no location too far for us. Where $\sigma$ is floor rigidity of liquid (N/m) and g is gravitational constant (m/s2).