Metal casting has been a fundamental process in manufacturing for thousands of years. This technique involves pouring molten metal into a mold to create intricate shapes and components. As technology has advanced, so too have the methods and materials used in metal casting. In this article, we will explore the evolution of these techniques, highlighting key innovations that have shaped the industry.

Ancient Metal Casting Techniques

Historically, metal casting can be traced back to ancient civilizations. The earliest known examples date back to around 4000 BC in Mesopotamia, where artisans used simple clay molds to create bronze tools and ornaments. These early methods laid the groundwork for future advancements.

- Sand Casting: One of the oldest methods, sand casting involves creating a mold from sand and clay. This technique is still widely used today due to its cost-effectiveness and versatility.

- Investment Casting: Also known as lost-wax casting, this method allows for high precision and is often used for intricate designs, such as jewelry and aerospace components.

Modern Innovations in Metal Casting

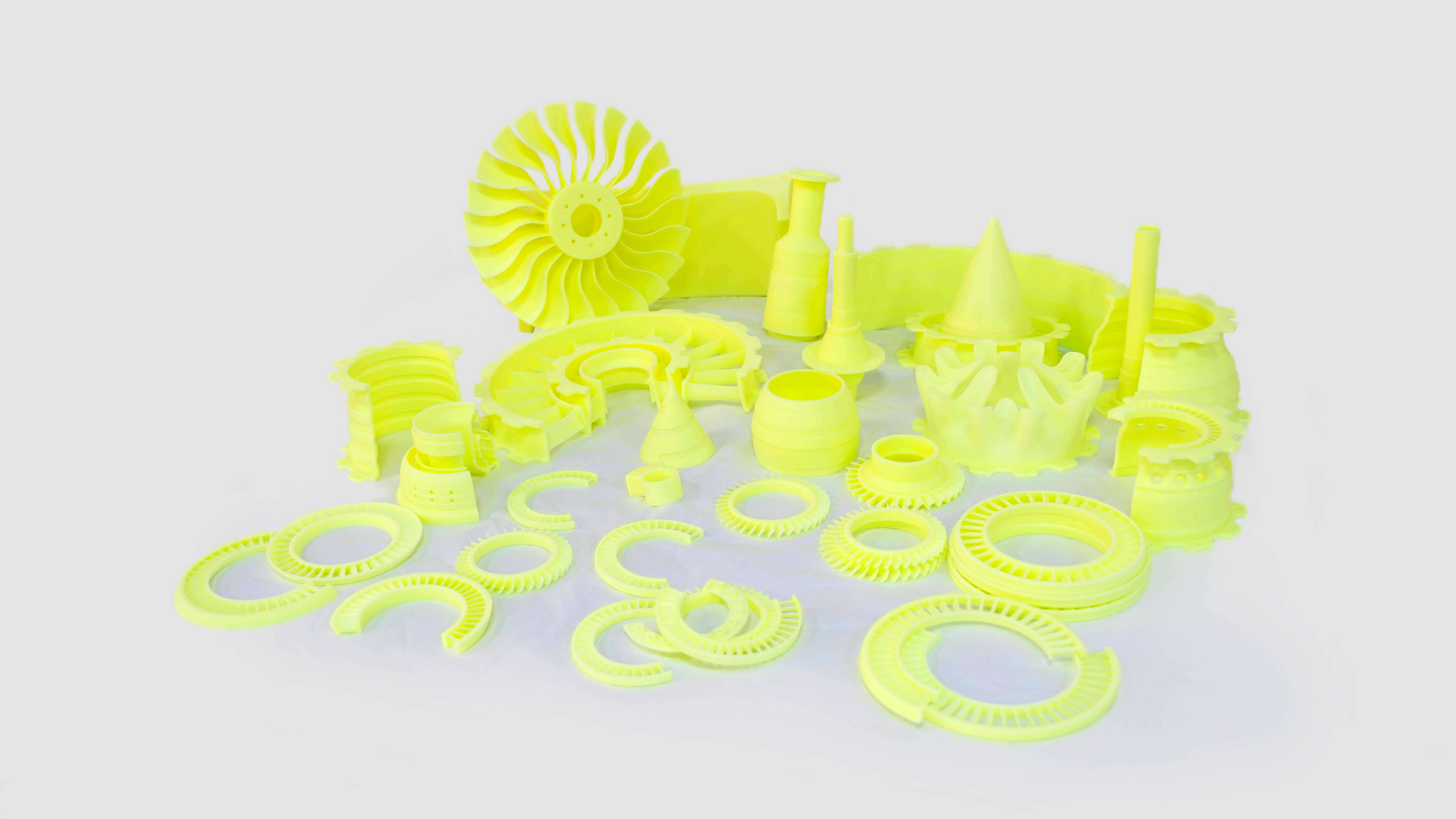

As we moved into the 20th century, the introduction of new materials and technologies revolutionized metal casting. The development of computer-aided design (CAD) and 3D printing has significantly enhanced the precision and efficiency of the casting process. For instance, the use of 3D-printed molds allows for complex geometries that were previously impossible to achieve.

"The integration of 3D printing into metal casting has opened new avenues for innovation, allowing for rapid prototyping and reduced lead times." - Industry Expert

Applications of Metal Casting Today

Today, metal casting is utilized across various industries, including automotive, aerospace, and medical. The ability to produce lightweight yet durable components is crucial in these sectors. For example, the aerospace industry relies heavily on investment casting for turbine blades, which must withstand extreme conditions.

Key Benefits of Modern Metal Casting Techniques

- Cost Efficiency: Modern techniques reduce material waste and labor costs.

- Enhanced Precision: Advanced technologies allow for tighter tolerances and complex designs.

- Material Versatility: A wide range of metals can be cast, including aluminum, steel, and titanium.

The Future of Metal Casting

Looking ahead, the future of metal casting appears promising. Innovations such as artificial intelligence and machine learning are expected to further optimize the casting process. Additionally, sustainable practices are becoming increasingly important, with many companies exploring eco-friendly materials and methods.

In conclusion, the evolution of metal casting from ancient techniques to modern innovations illustrates the adaptability and resilience of this manufacturing process. As technology continues to advance, we can anticipate even more exciting developments in the field.

References