3D printing has revolutionized the way we create objects, but it is not without its challenges. In this article, we will delve into 3D printing troubleshooting: 15 most common problems & solutions to help you navigate the complexities of this technology. Whether you are a beginner or an experienced user, understanding these issues can significantly improve your printing outcomes.

Common 3D Printing Problems

When engaging in 3D printing troubleshooting, it is essential to recognize the most frequent issues that can arise. Here are some of the typical problems:

- Filament Jamming: This occurs when the filament gets stuck in the extruder, preventing it from feeding properly.

- Layer Separation: This happens when layers do not adhere well to each other, leading to weak prints.

- Stringing: This issue manifests as thin strands of plastic between parts of the print.

- Warping: Warping occurs when the edges of the print lift off the build plate.

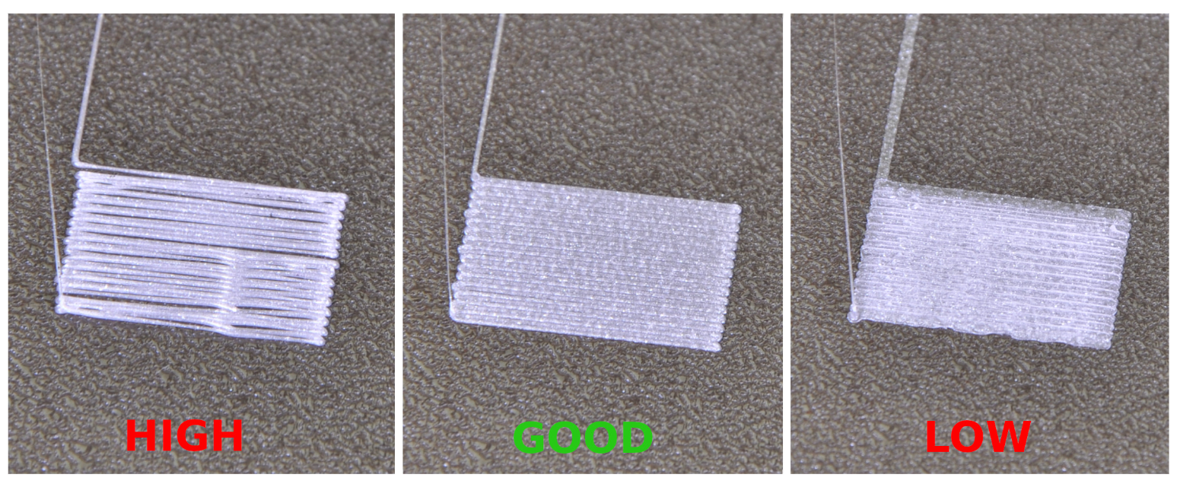

- Under-extrusion: This results in gaps in the print due to insufficient filament being extruded.

- Over-extrusion: This leads to excess filament being laid down, causing blobs and zits on the print.

- Bed Adhesion Problems: Prints may not stick to the build plate, leading to failed prints.

- Inconsistent Layer Height: This can cause uneven surfaces and poor print quality.

- Electrical Issues: Problems with wiring or power supply can interrupt the printing process.

- Temperature Fluctuations: Inconsistent temperatures can affect filament flow and print quality.

- Print Head Clogs: A clogged nozzle can halt the printing process entirely.

- Incorrect Print Settings: Using the wrong settings can lead to various print failures.

- Material Issues: Poor quality or incompatible materials can cause numerous problems.

- Software Errors: Bugs in slicing software can lead to incorrect print paths.

- Mechanical Failures: Issues with the printer's hardware can disrupt the printing process.

Solutions to Common 3D Printing Problems

Now that we have identified the common issues, let’s explore potential solutions. Here are some effective strategies for 3D printing troubleshooting: 15 most common problems & solutions:

- For filament jamming, ensure the filament is properly loaded and check for any obstructions in the extruder.

- To prevent layer separation, adjust the print temperature and ensure proper bed adhesion.

- Minimize stringing by optimizing retraction settings in your slicing software.

- Use a heated bed to combat warping and ensure the first layer adheres well.

- Check the extrusion multiplier to resolve under-extrusion or over-extrusion issues.

- Regularly clean the print bed and use adhesives like glue sticks to improve bed adhesion.

- Keep your printer's firmware updated to avoid software errors.

- Inspect wiring and connections to address electrical issues.

Conclusion

By understanding the 3D printing troubleshooting: 15 most common problems & solutions, you can enhance your printing experience and achieve better results. For a more comprehensive guide, consider visiting this resource. With the right knowledge and tools, you can overcome the challenges of 3D printing and unlock its full potential.